Experience

We have been providing state-of-the-art RF coaxial and multiconductor transmission line assemblies for military and commercial applications since 1957. With the lowest weight and smallest bend radius of any RF cable, these assemblies still set the industry standard for high performance and reliability in all types of hostile or adverse environments.

Our cable assemblies are qualified to MIL-T-81490, MIL-C-39012, and other military and commercial specifications.

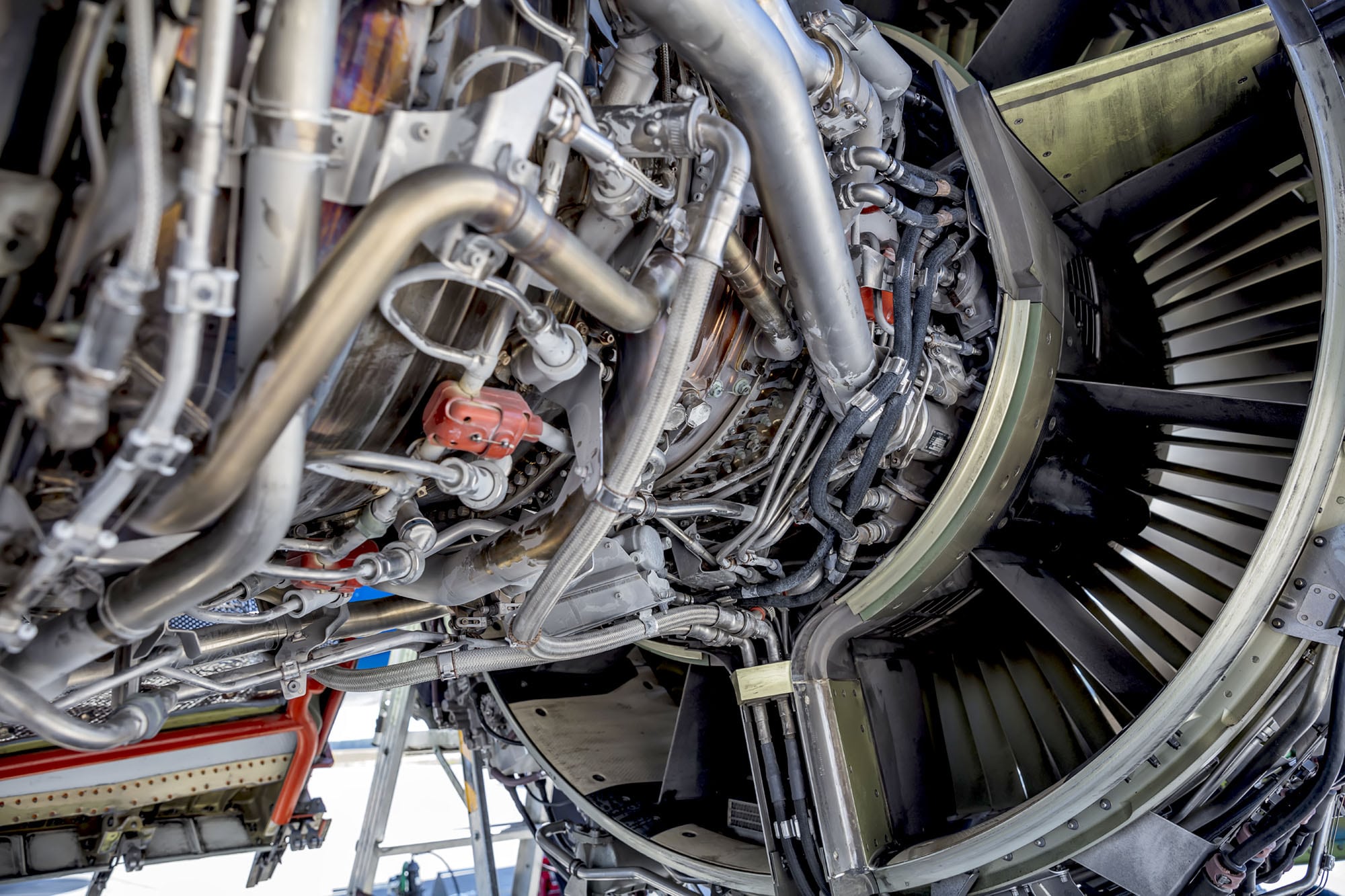

Applications include: AH-1, AH-64, AV-8B, B-1B, B-2, C-17, C-130, F-5, F14, F-15E, F16, GPS, J-Stars, MX missile, SR-71, Space Shuttle, SPS-49, Tomahawk, U-2, Trident, UH-60

Reliability

Our cable assemblies feature rugged all-welded construction, hermetic connectors and silicon dioxide (SiO2) insulation. SiO2 provides unparalleled phase and attenuation stability over a wide temperature range significantly improving system accuracy and reliability in all critical situations.

High performance

Other features include:

- 80% velocity of propagation

- EMI Shielding to -120 dB

- -270 to 950 degrees C operation

- 300 – 500 lb. connector pull-off

- vibrations 20Gs 50 to 2000 Hertz

- capacitance – 25 pf/ft.

- 0.1 to 26 GHz

Lowest weight and smallest bend radius of any RF cable

In today’s aircraft, space and weight are at a premium. Our semirigid cable is typically 30-50% smaller and lighter than comparable PTFE cables. Meggitt assemblies offer the lightest weight per diameter of any cable available. The small bend radius of SiO2 allows 90 degree bends that replace bulky right-angle connectors which add considerable weight and insertion loss. Installation in confined or extremely tight locations can be easily accomplished. A bend radius as small as 1.5 times the diameter of the cable can be accommodated.

Transition cables for lowest loss

We also offer a broad range of transition assemblies. These cables provide the lowest possible loss with maximum flexibility by using large diameter cable for the greater portion of a cable run and a small diameter where flexure is most important. A 50 ohm impedance is maintained throughout the cable assembly.

Power handling

Meggitt has the off-the-shelf designs for high power applications up to 1 Kw C.W. at 10GHz. Power capability is typically limited by connector selection and design.

Stability offers broad applications

Semirigid cables are not limited to RF applications. The cables are ideal wherever low-level signals are susceptible to EMI or crosstalk degradation. At 25 pf/ft. and shielding to -120 dB, these cables deliver the most accurate signal of any transmission line available. High-speed data and instrumentation signal, from sensitive test equipment and engine/machinery monitoring devices are applications that benefit from the exceptional electrical stability that SiO2 offers.

Multiconductors

Meggitt also offers multiconductor cables for aircraft electrical power distribution systems with up to 10 conductors installed in a 1/2″ cable assembly. This cable weights only 0.3