Composites for Aero Engines

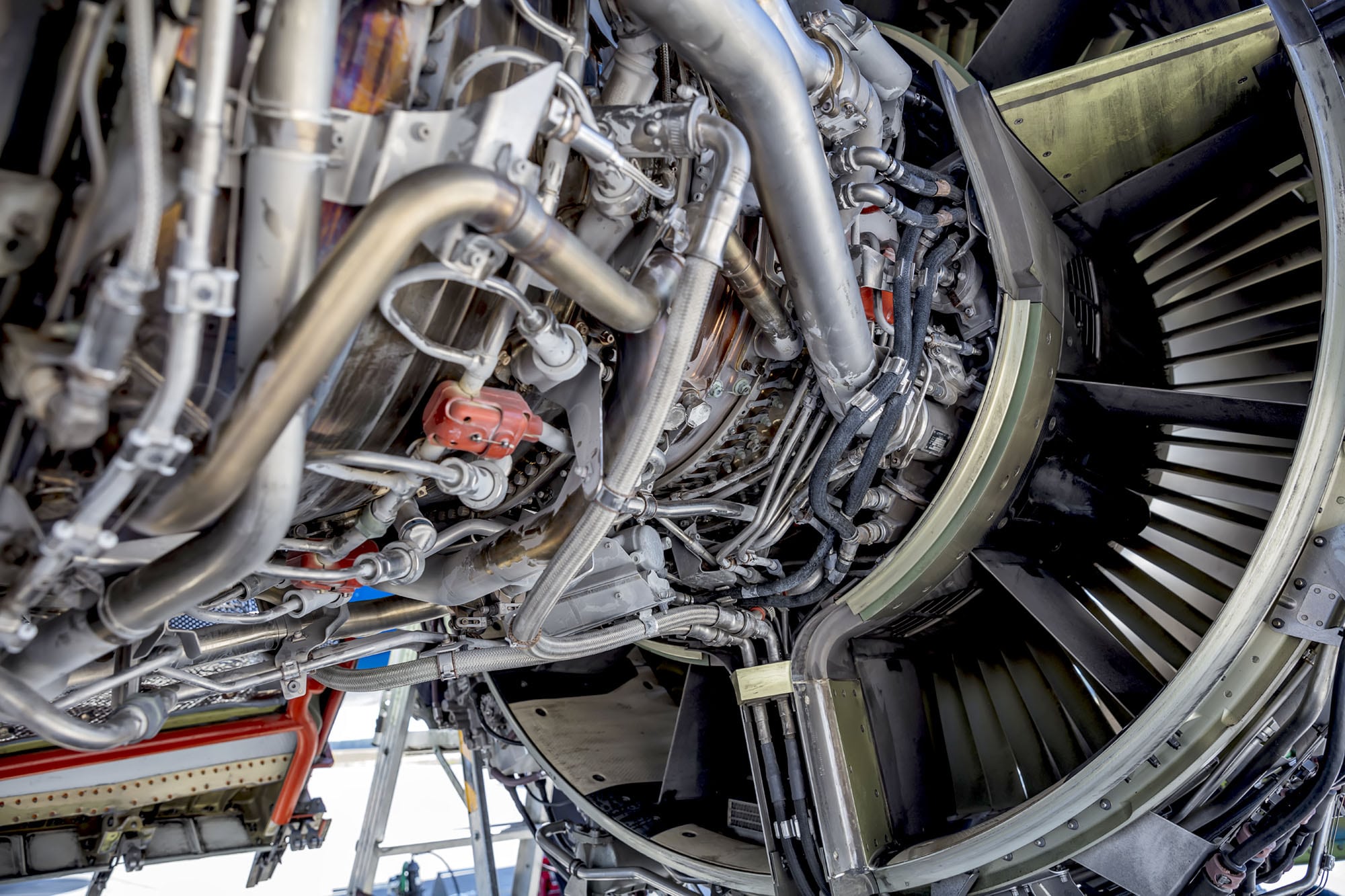

From the F135 to the LEAP engines, we enable customers to meet and exceed the most significant engine requirements in industry. We specialise in composite components for engines, offering more advanced state-of-the-art manufacturing capabilities and processes than competing businesses in the industry. Our engine components are found on several major high-rate commercial and military platforms in the world.