Electro-thermal Ice Protection

We are the leading provider of ice protection systems. Our solutions integrate heated structures within our advanced composite materials for high strength, reduced weight and superior corrosion-resistance.

We are the leading provider of ice protection systems. Our solutions integrate heated structures within our advanced composite materials for high strength, reduced weight and superior corrosion-resistance.

Our smart control logic built into our ice protection systems reacts to flight conditions in order to provide the right amount of power, in the right place, at the right time.

From simple composite monolithic to complex hybrid sandwich structures using resin systems operating at over 200C – we can provide the optimum solution.

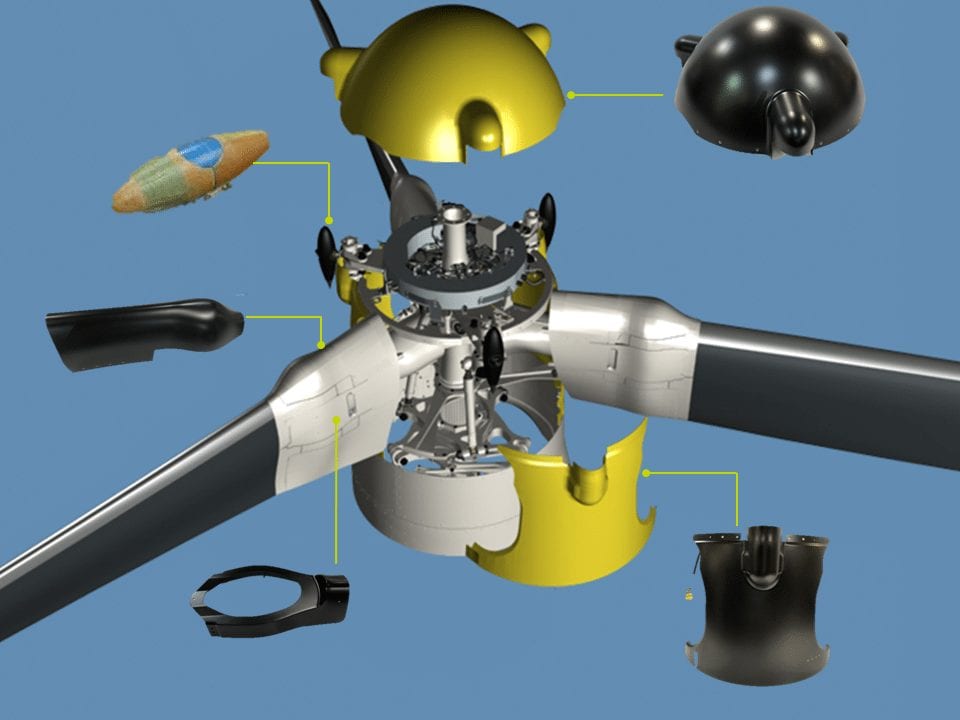

Courtesy Bell Helicopters

Our ice protection systems, whether bleed air or advanced electro-thermal solutions, protect a wide range of critical aircraft components, including:

Our strength lies in the ability to combine 50+ years of ice protection experience with advanced analytical tools.

We ensure that operating economics – weight, cost, and reliability – are all factored into our ice protection equation to optimise your customised solution. Our engineers use 3-D flow, impingement prediction, catchment efficiency and heat transfer modelling to maximise the system performance, reduce labour hours, and minimise the overall cost of the programme.

Our engine inlets are designed with electro-thermal ice protection and high temperature sensors embedded into a composite laminate structure and then bonded to metallic surfaces. This allows the development of smaller, lighter, and more efficient engines.

We use computational fluid dynamics to ensure sufficient laminar air flow is maintained throughout the engine’s operating range.

Our electro-thermal technology protects the leading edges of helicopter blades, spinner cones, skirts and fairings on many commercial and military programmes.

Our approach to structural excellence is based on optimising load, weight and cost without compromising performance and reliability. This is why we work with the major airframers to integrate our pioneering electro-thermal ice protection and advanced heating elements into their blade systems.

Proven on multiple engine inlet programmes, our composite-based electro-thermal technologies provide a low risk ice protection solution for fixed wing aircraft as well.

We integrate anti-ice, de-ice, and runback control to provide continuous heat to a wing’s leading edge. At the same time we deliver energy savings by varying the intensity of the heat across additional zones on the wing’s upper surface according to the severity of the icing environment.

When needed, we can de-ice a wing’s underside economically by switching heat between discrete zones in a continuous cycle according to the aircraft’s flight conditions.

We proudly design and manufacture our ice protection systems in Rockmart (GA) and Shepshed (UK).

Our composite solutions for ice protection systems can be found on a vast range of commercial and military platforms.

Our customers include Airbus, Beechcraft, Bell, Boeing, Embraer, Hawker, Leonardo, Lockheed Martin, Piaggio, Rolls-Royce and Sikorsky.

At Meggitt, we can provide you with an ice protection system specifically designed for your application. To discuss what you need in more detail, please contact us.