Piezoelectric Ceramics

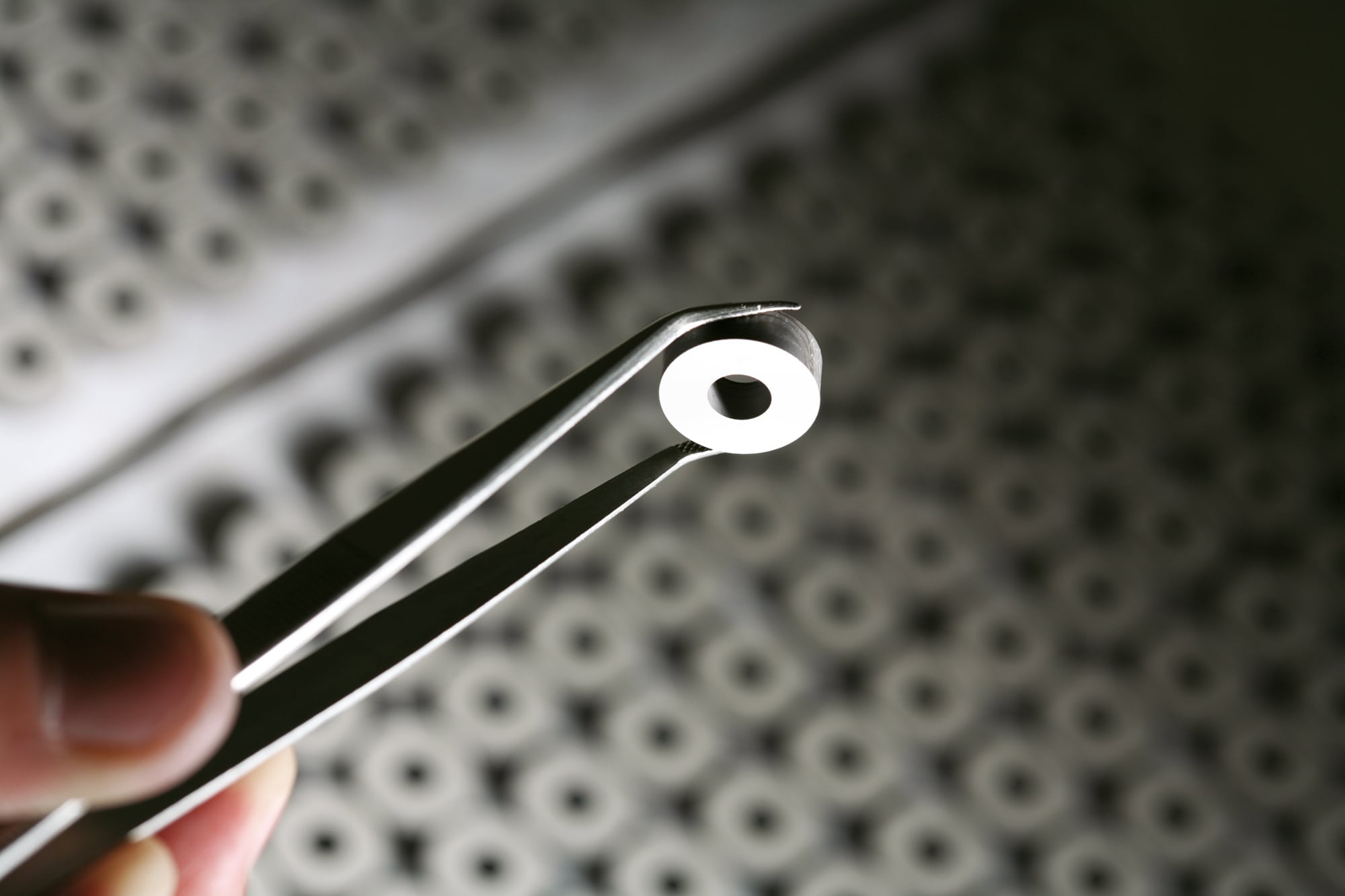

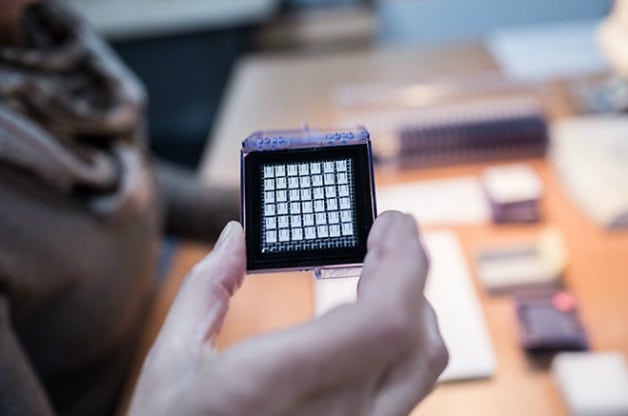

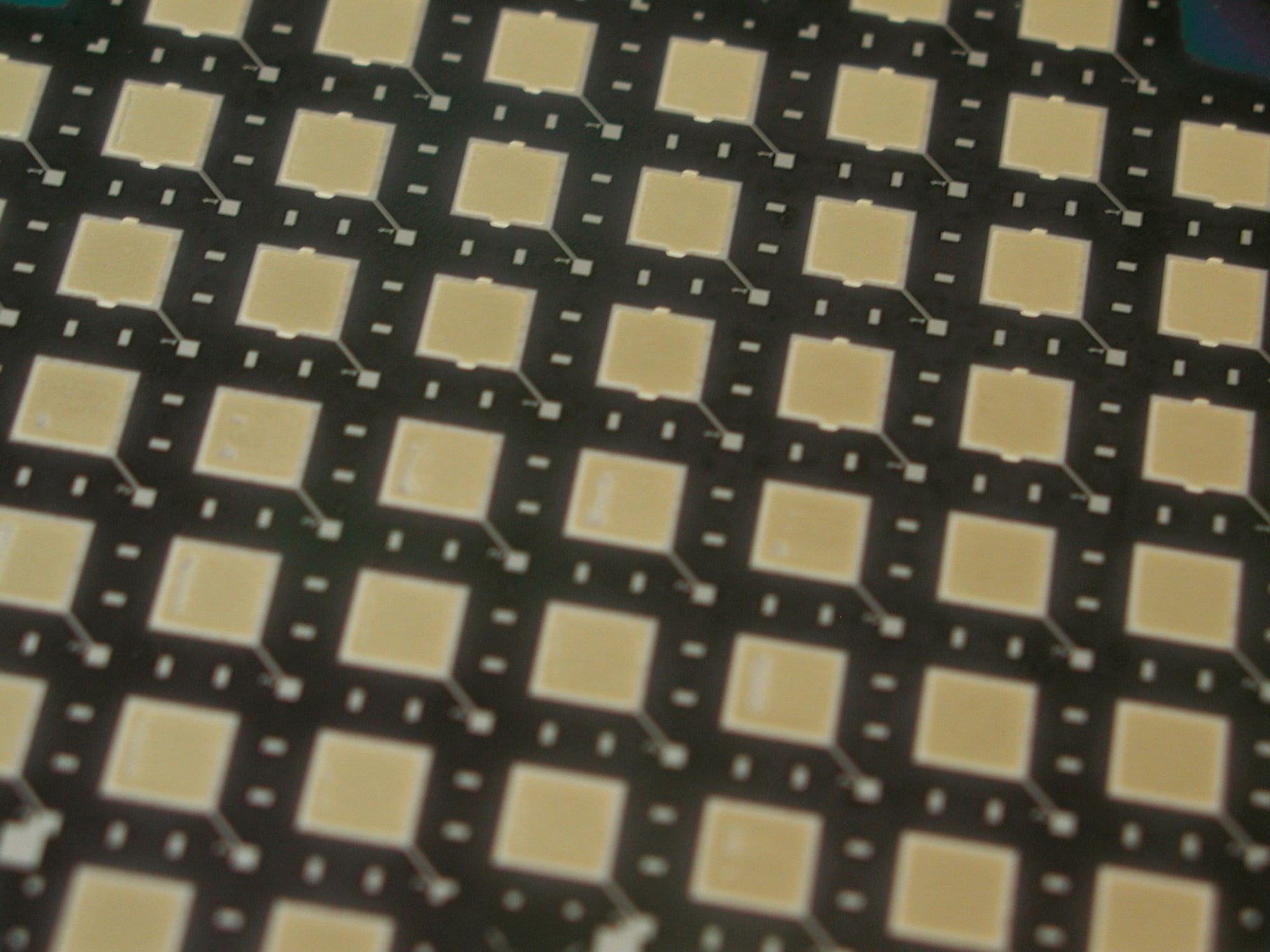

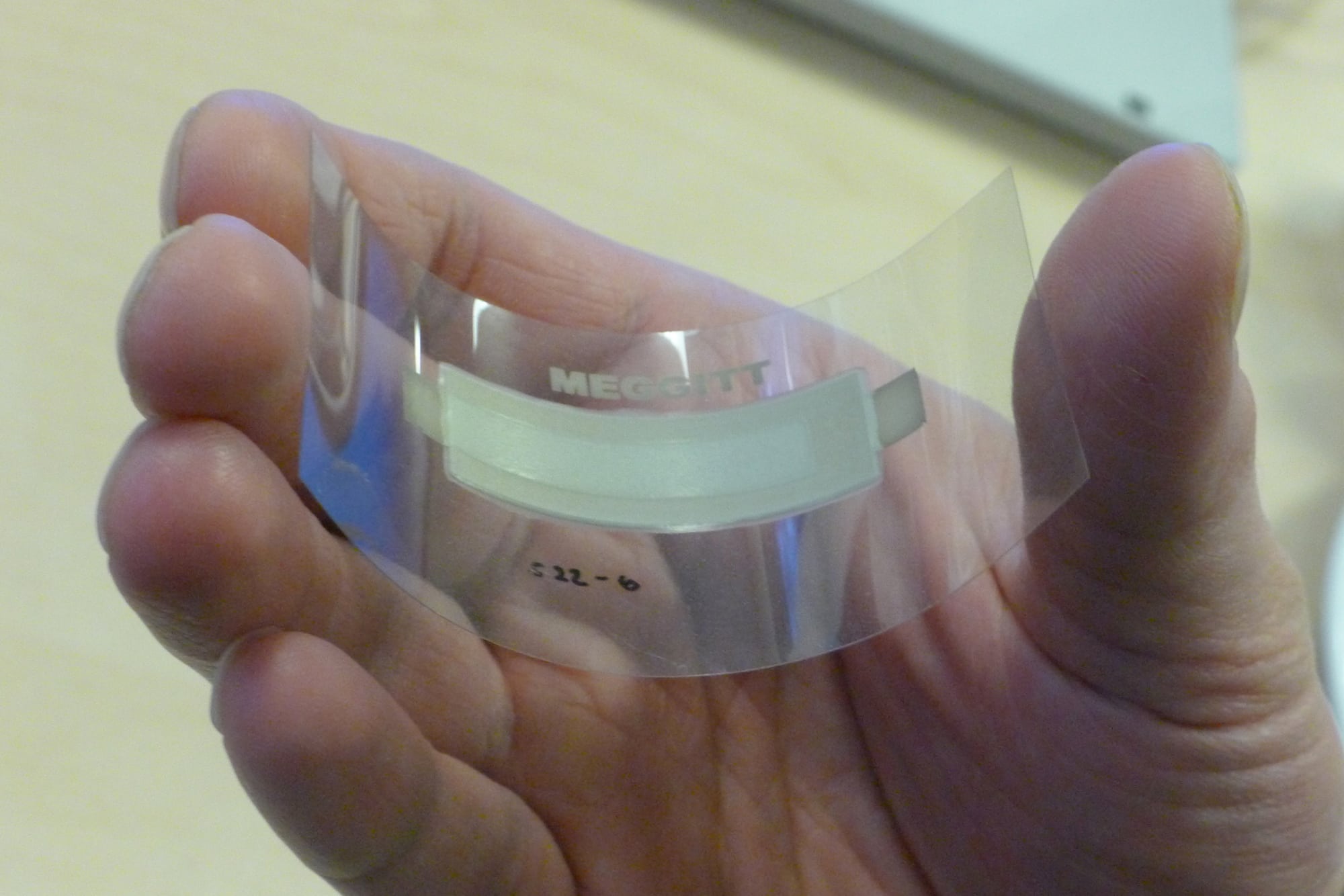

High quality piezoceramics for medical and industrial applications. Our products have the highest batch reproducibility in the industry. This allows our customers to optimise their designs and improve performance and production flow.