Our roots date back to the dawn of aviation.

In 1907 Serck Radiators was founded in the UK by Peter Oscar Serck to supply radiators to the fledgling aircraft industry.

In the 1930’s these designs were adapted for the Rolls-Royce Merlin engine used to power the Spitfire aircraft.

In the 1930s in the USA, Stewart Warner was producing radiators and gasoline-fired heaters for the automotive industry.

In the 1940’s we designed and manufactured combustion heaters and heat exchangers for both military vehicles and aerospace applications, including the heat exchanger for the Rolls-Royce Merlin engine used to power the Spitfire aircraft. By 1945, we had supplied 65,000 radiators and 100,000 air coolers for aircraft in the UK.

In the 1960s, Stewart Warner South Wind Corporation became one of the world’s leading suppliers of large aluminium heat exchangers for the chemical processing and air reduction industries.

In 2004, Meggitt acquired the Dunlop Group (including the heat exchanger technology from Serck Aviation and Stewart Warner South Wind)

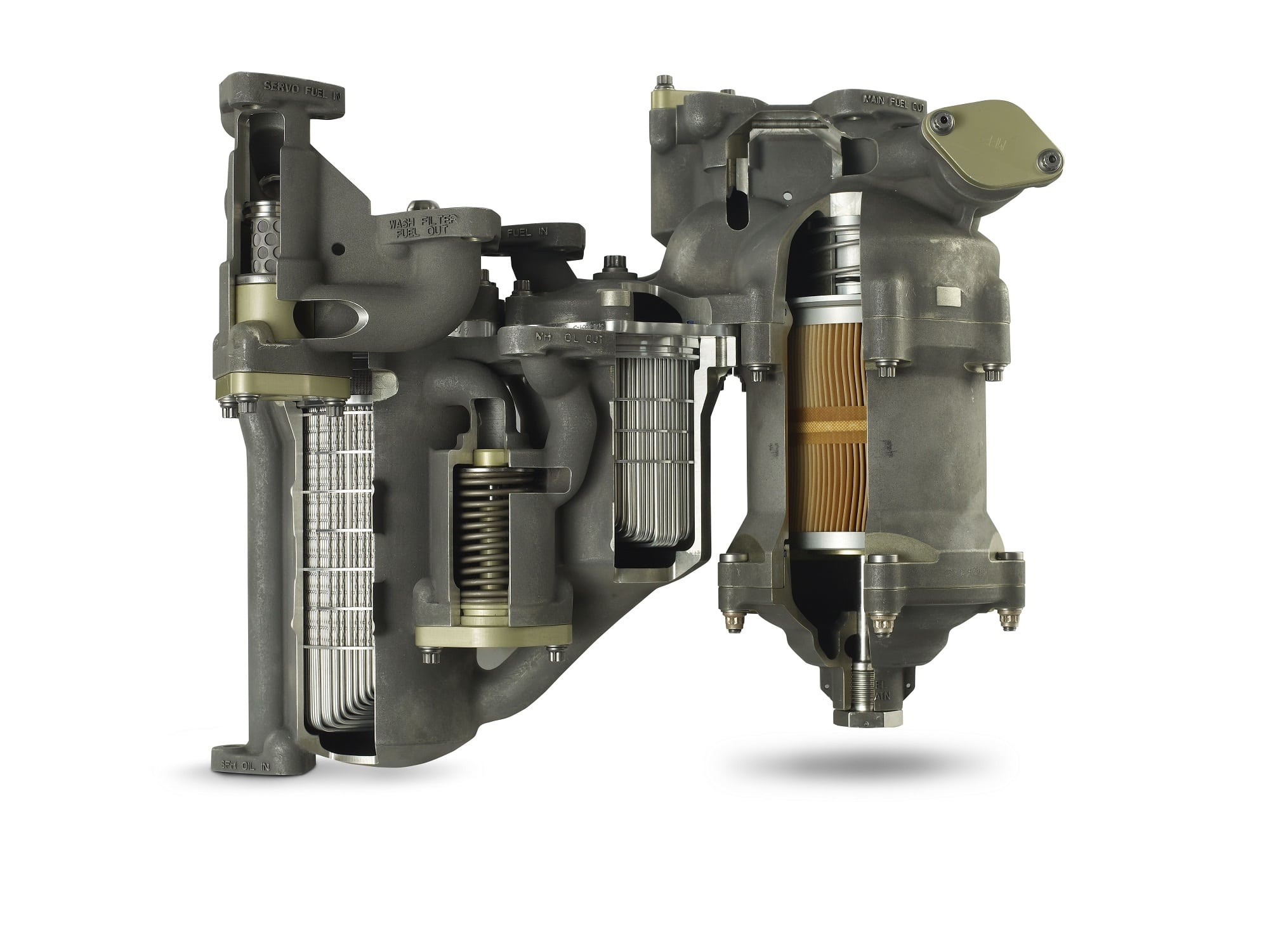

By the 21st century, our heat exchangers have evolved to become the multiple flow, multiple circuit heat management systems needed by the most advanced aero engines. These compact and lightweight units now perform multiple functions including:

- Control engine and airframe oil and fuel temperatures

- Control fuel nozzle temperature to prevent fuel carbonisation

- Cool bearing air and turbine blades

They are used on the majority of the latest aero-engines including LEAP, PurePower and the F135.