Wheels and Brakes for Aerospace and Defence

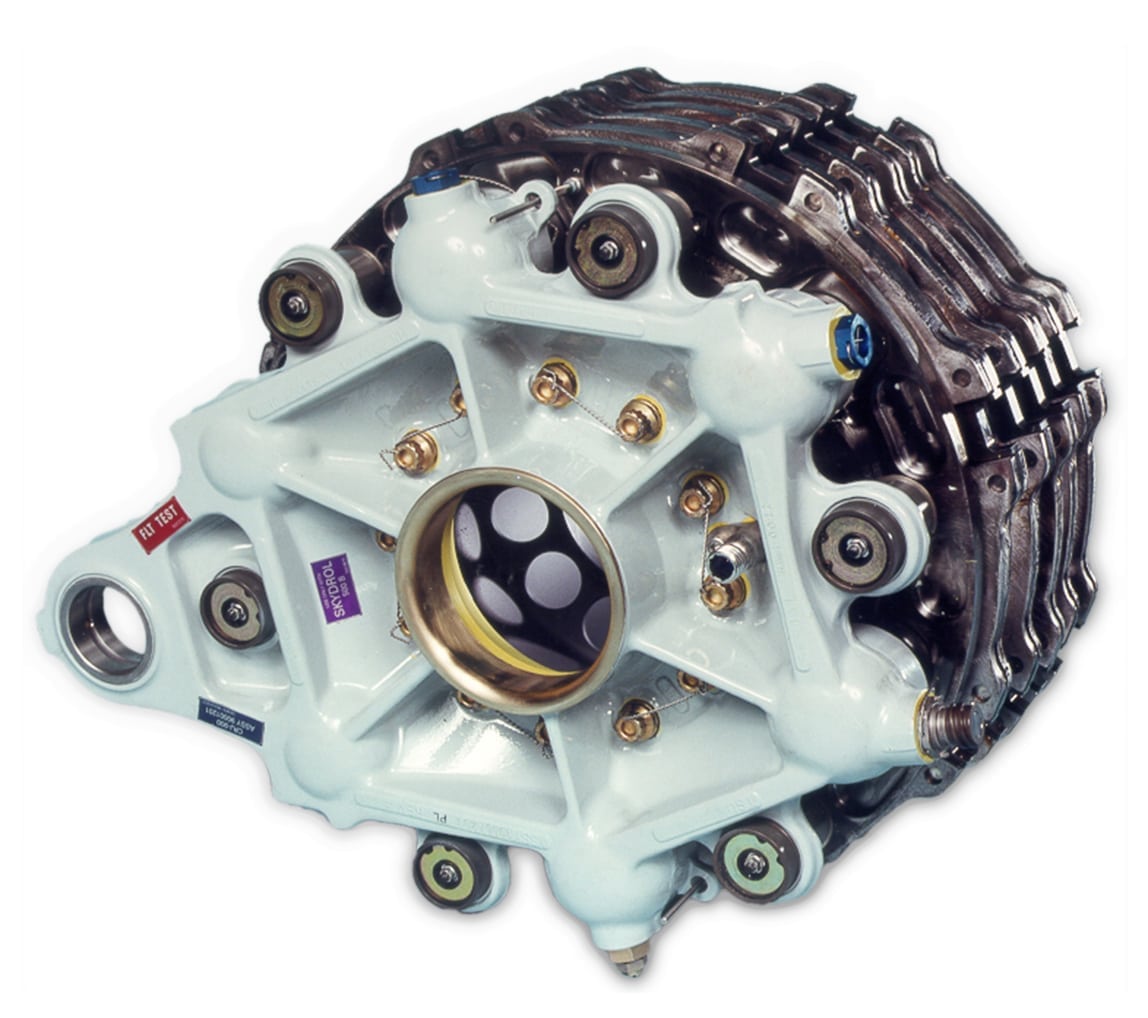

From the first multi-disc steel aircraft brakes in the 1930's to the first electric braking system on a commercial aircraft, Meggitt has been the technology leader. We are one of only a few companies that can provide complete integrated braking systems - the wheels, brakes and brake control element.